It’s no secret that label printers are under greater pressure than ever before. In addition to an evolving retail landscape that demands quality and agility in supply, without sacrificing quality, supply chain shortages and rising inflation continue to provide significant challenges.

However, the well-documented market difficulties could light the path towards a more resilient label printing industry. As we head into 2023, printers are switching from surviving to thriving, and the race is on to stay ahead of the market.

In a market that is still seeking stability, how can printers stay competitive while ramping up operations across the board to meet a new raft of demands?

At Pulse Roll Label Products, as a leading supplier of UV flexo inks and varnishes, we get a valuable ‘top-down’ view of the supply chain, and we see three fundamental rules for label printers to build – and keep – a valuable edge against stiff market competition.

- Lower industrial energy use

- Boost efficiency, to accomplish more with less

- Eliminate waste

But what does that look like in practice – and where can a trusted ink and coatings partner like Pulse help?

Lower industrial energy use

For printers, margin is everything. This means that overheads must be kept under tight control in order to sustain valuable growth in what is an increasingly competitive label printing sector.

There are numerous options on the table, including both the use of renewable energy sources to power facilities, as well as choosing equipment and technologies that actively reduce energy use through operating more efficiently. Examples include water-washable flexo plates that don’t require water to be heated to high temperatures in order to clean effectively.

An important way to reduce overall energy use is to trust an experienced ink and coating partner, like Pulse. With a technical team supporting printers of every size, Pulse can help ensure every print run impresses, and crucially, reduces the risk of errors and energy-consuming corrective runs.

Pulse understands label printing inside and out, and its comprehensive tech support ensures printers are always on the front foot.

Boost efficiency

A key competitive edge can be gained through finding new efficiencies in the printing supply chain. For many printers, process efficiency is the difference between a standard service for customers, and one that delights. Of course, efficiency as a goal is not new, but it is ever more important when the printing industry is so competitive. An efficient and optimised printing supply chain brings tighter cost control, consistent and repeatable quality and the precision that eliminates waste from errors.

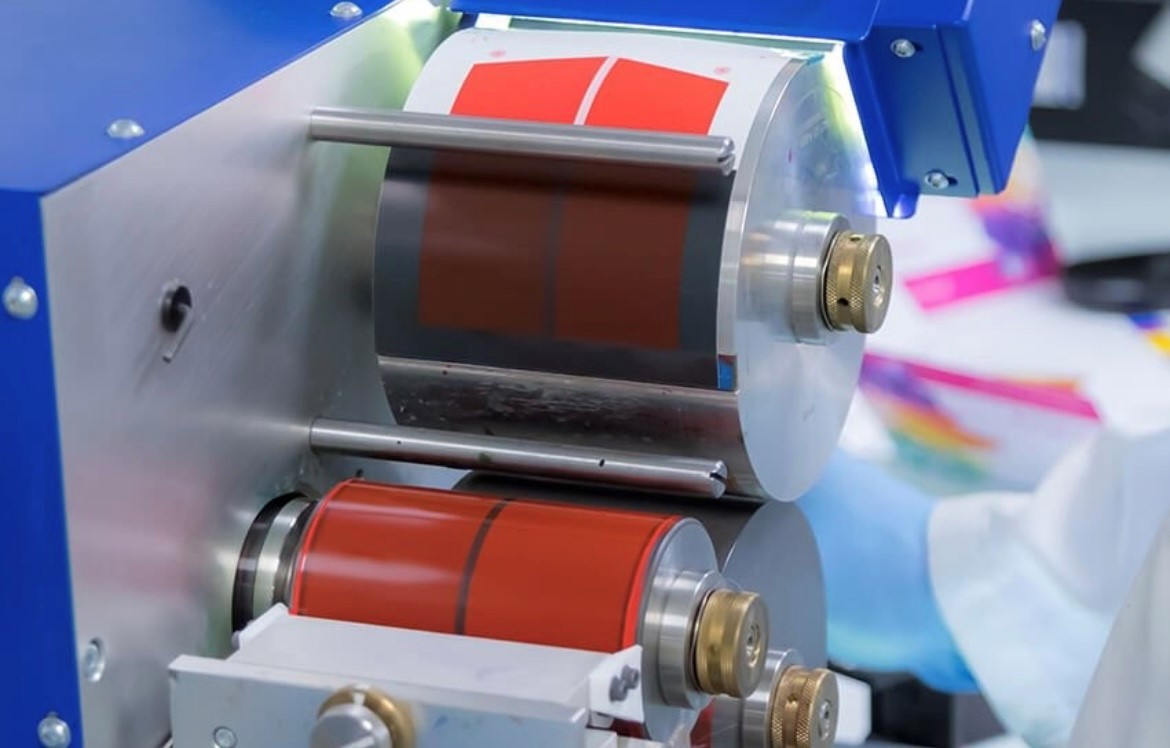

At Pulse, we proudly champion Fixed Anilox Printing as a way to simplify and standardise UV flexo label printing. The technique enables printers to produce any spot colour on one volume of anilox. The efficiency benefits are sizeable; Fixed Anilox Printing means a fixed set can be installed, and rollers do not need to be changed in-between jobs for maximum volume, speed and machine uptime.

Providing high-speed makeready and up to a 30% reduction in ink consumption, Fixed Anilox Printing grants printers another way to deliver service that wows and stands out in an ever more crowded market.

The core to the success of Fixed Anilox Printing, Pulse has developed PureTone, a line of high-strength single-pigment inks supported by a bespoke colour mixing database. Ideally suited to Fixed Anilox Printing, PureTone’s high strength bases deliver right-first time printing, to maintain production efficiency and consistent throughput. With vibrancy so important to today’s printers and their brand partners, PureTone can deliver a Delta E of less than 2, and exceptional consistency, with ease.

PureTone inks also directly challenge one of the most significant process challenges for printers – maintaining colour precision through digital and flexo print. For many printers, short runs on digital eventually make way for longer high-volume runs on a flexographic press, but that’s not always an easy transition to make. With PureTone, however, the high strength base and single-pigment formulation mean that in tandem with a calibration software, that jump can be made simple with run-to-run consistency and repeatability across print methods. In turn, this means scaling jobs becomes simpler, and the printer becomes more agile and better able to meet its brand customers’ needs.

With PureTone, however, the high strength base and single-pigment formulation mean that in tandem with a calibration software, that jump can be made simple with run-to-run consistency and repeatability across print methods. In turn, this means scaling jobs becomes simpler, and the printer becomes more agile and better able to meet its brand customers’ needs.

Reduce waste

When we talk waste reduction, we often tie this in with sustainability. While that’s true and remains a key area of focus, we cannot dismiss the financial impact of waste on a label printing business.

Today’s supply chain is often complex, and with each touchpoint there is the potential for waste. This can be in terms of physical material, such as substrates, as well as in intangibles such as time, energy and cost. A label printer that is able to take a granular view of its processes and reduce the risk of waste at each individual stage is, as a result, building a tighter and more effective operation.

One of the most effective technologies available today to printers is digital automated workflow management. The core of their value lies in reducing manual touchpoints and the need for human intervention, freeing up resources as a result. While having operatives remains essential, many of the day-to-day repetitive tasks for printers can be digitised, enabling workforces to focus on other value-adding tasks.

This wave of digitisation extends to proofing and approval, which can dramatically cut down time and logistics pressures. With digital approvals management, for example, the risk of errors is cut down and with it, the potential for costly and wasteful print re-runs.

In today’s market, printers must seize every competitive edge available to win orders and make long-term growth sustainable. With the assistance of an experienced ink partner like Pulse, printers can arm themselves with new efficiencies and a crucial critical edge as market competition tightens.