drupa 2024

drupa 2024 is rapidly approaching and RR PRINT is ready to welcome you! Check here where you can find us in Düsseldorf.

Let's make flexo printing simple again!

Something has been cooking for a while. It's about making the complex simple. It's all about speed, reliability, and consistency. It's about pit stops in Formula 1 and how this relates to your printing machines.

BOOM!! The brand colours were spot on!

A story about a project which has moved print tasks from digital to flexo. ECG is complete standardization of your machine, by which you run CMYK + Orange, Green and Violet instead of the many, many spot colours.

Monolox proves a smash hit at Labelexpo Europe

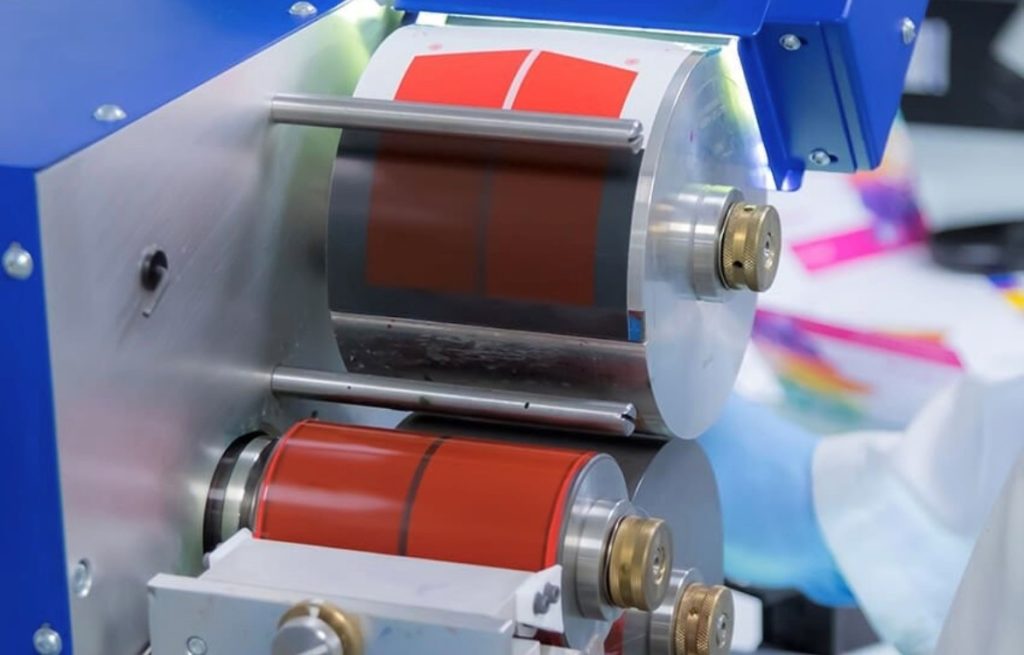

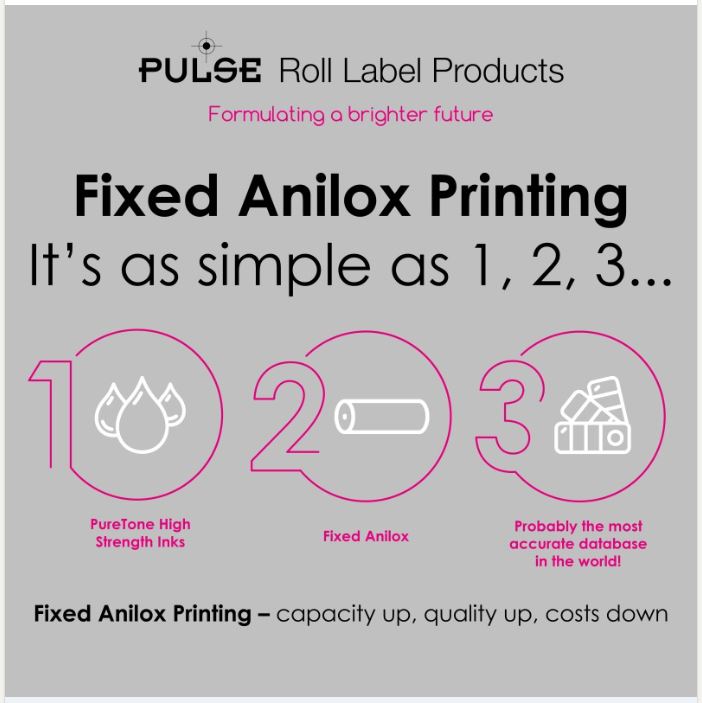

Attendees flocked to the Pulse Roll Label Products (Pulse) booth at Labelexpo Europe last week to learn how Monolox® Fixed Anilox Printing and the PureTone® ink range are revolutionising flexo label printing.

LabelExpo 2023 – meet RR PRINT in Brussels!

Connect with RR PRINT at LabelExpo 2023! Come and see the latest print solutions at the Pulse Stand Stand 3C64 in Hall 3. Call now to make an appointment!

Order your favourite ProCoate varnish directly on our webshop

At RR PRINT A/S, we are very passionate about coatings and dedicated to helping printers achieve their best results with our wide range of functional coatings for the printing industry. We combine technical expertise and a deep knowledge of coatings to deliver exceptional products and a service which will optimize your printing processes and improve your production quality.

Simplify your label printing with Monolox – Fixed Anilox Printing

Whether you’ve invested in digital press technology, are running the latest flexo press, or are using seven colour process printing; if you’re interested in reducing wasted time, materials, or energy – then Monolox Printing could be for you.

PureTone DC: the cure for rising energy costs

UK headquartered narrow web printing ink specialist Pulse Roll Label Products is helping printers beat rising energy bills with the launch of its new dual cure UV LED ink range, PureTone DC®.

Staying competitive in the label printing market – Three fundamental rules

In a market that is still seeking stability, how can printers stay competitive while ramping up operations across the board to meet a new raft of demands?

Pulse Roll Label Products shares insights into revolutionary Fixed Anilox Printing

Pulse Roll Label Products (Pulse), a leading supplier of UV flexo inks for the global label printing industry, has shared its insight to Fixed Anilox Printing – a game-changing technique to simplify and standardise UV flexo label printing.